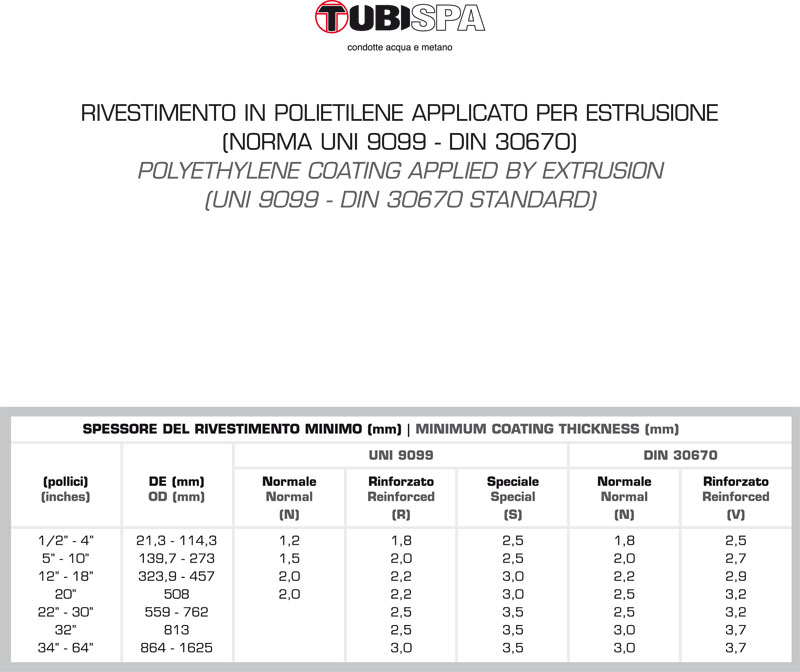

The external coating in polyethylene is applied on steel pipes for buried or submerged pipelines for water and methane as well as on gas distribution pipes. Coating thickness depends on pipe diameter and which UNI 9099 typology (see table) is requested.

The three layers polyethylene coating offers a long lasting corrosion protection, high resistance and strong adhesion with service temperature from -20° C to a maximum +60/80° Celsius.

The black pipe is sandblasted by metallic grit to SA 2.5 according to ISO 8501-1 standard, then a first layer of primer is applied, the second layer consists in polyethylenic adhesive and the third in polyetyhlene layer. After cooling the coating is cut back on pipe-ends and checked as per UNI 9099/DIN 30670: visual inspection, control on thickness, dielectric continuity and technological tests.